Not All Welding Automation Is Built the Same

If you’re exploring robotic welding for your shop, you’ve likely run into more than one “right” answer. But behind the similar product names and slick brochures, there are two fundamentally different ways vendors approach welding automation.

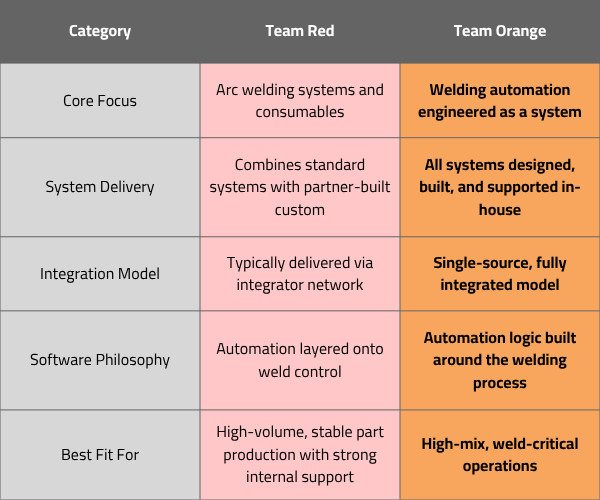

This article compares two dominant models in the market:

- Team Red – A well-known name in arc welding that combines standard automation systems with third-party integration.

- Team Orange – A single-source supplier that designs, builds, and supports complete welding automation systems from the ground up.

Your job isn’t to pick a color, it’s to pick the approach that best fits your operation. Let’s walk through what makes them different, and where each performs best.

Comparing Two Welding Automation Models

What Team Red Offers

Team Red brings a strong presence in welding equipment, especially power sources and consumables. Their automation line includes:

- Standard cells: Designed for repeatable use cases and fast deployment

- Custom systems: Delivered through integrators for specialized setups

This model is ideal for manufacturers who are already embedded in the Red ecosystem, or those who have an experienced automation team and prefer to work through a local integration partner.

What to consider:

If your parts are consistent and your process is well-established, this approach may check the right boxes. But when part variation increases or operator skill levels shift, relying on multiple vendors can increase friction.

Where Team Orange Takes a Different Path

Team Orange delivers full-spectrum welding automation—from robot to torch to software—without outside integrators. Everything is engineered in-house, so there’s no need to align across separate suppliers or service models.

Benefits include:

- A single point of contact

- Consistent service and training

- Faster resolution of issues

- Weld-quality decisions made by welders, not just programmers

“We didn’t want to manage three vendors. We just needed someone to own the weld, the system, and the outcome.” — Midwest Trailer Fabricator

Which Approach Is Right for Your Operation?

Choose Team Red if:

- You already run red-branded equipment and want compatibility

- You have a trusted integration partner

- Your product line is stable and high-volume

Choose Team Orange if:

- Your parts change week to week

- Weld consistency matters more than sheer speed

- You want fewer vendors and more accountability

- Your internal team needs a partner, not just a product

Final Thought: Automation Isn’t Just Hardware, It’s Philosophy

Welding automation success depends less on the arm, and more on the team behind it. When systems are integrated without welding expertise, performance suffers—even with top-tier robots.

Understanding how different providers build and support their systems helps you make a smarter investment. You’re not just buying a robot. You’re building a capability.

Team Orange was built for that.

Still weighing your options?

Let’s talk through your parts, process, and goals. We’ll give you a straight answer on whether single-source automation fits your operation.