“How Much Does a Welding Robot Cost?” – The Most Common, Yet Most Misunderstood Question in Automation

If you’re exploring robotic welding for your operation, whether you’re an agricultural equipment builder in Iowa or a trailer fabricator in Ontario, you’re asking the same thing:

“What’s this really going to cost us?”

The answer isn’t as simple as a sticker price. Welding automation isn’t a commodity: it’s a capability. And like most high-value tools, the cost depends heavily on your goals, parts, and support expectations.

Let’s walk through what real buyers in 2025 are paying, what’s driving those numbers, and how to budget with confidence, not guesswork.

1. Real-World Cost Ranges: What You Should Expect to Spend in 2025

Here’s a high-level breakdown of current price brackets for robotic welding systems in North America:

| System Type | Typical Price Range (USD) |

|---|---|

| Pre-Engineered Welding Cell | $130,000 – $250,000 |

| Custom Robotic Welding System | $250,000 – $600,000+ |

| Complex Multi-Robot Systems | $600,000 – $1.2M+ |

Pre-engineered cells—which include the robot, power source, positioner, safety enclosure, and controls—are the most common entry point for job shops and small-to-mid-sized manufacturers.

Custom solutions introduce added cost/capability through material handling integration, vision systems, fixturing complexity, and tailored programming.

High-end, multi-robot lines are usually implemented by large OEMs with high throughput demands, product consistency, and a strong in-house engineering bench.

2. What Actually Drives the Price of a Robotic Welding System?

Price isn’t just about the robot. Here’s what really moves the number up (or down):

A. Part Complexity & Variability

The more variation and joint types your parts have, the more tooling, fixturing, and programming is needed. A simple two-joint weld on a repeatable part is less costly than a part family with five weldment geometries.

B. Required Throughput

Are you trying to double output or reduce cycle time by 10%? Speed comes at a price—especially when tandem welding, servo-controlled positioners, or vision-guided robotics are required.

C. Operator Interface & Training

Intuitive HMIs and easy-to-use software can reduce long-term training costs. However, that often means a more robust upfront investment in integrated controls and programming support.

D. System Scope & Integration

Off-the-shelf pre-engineered cells are more budget-friendly than custom systems that integrate conveyors, scanners, or customer-specific workflows.

E. Service Expectations

Some buyers want a white-glove install with regional field support and a multi-year service agreement. Others are fine with phone support and minimal onsite assistance. The right support model adds to the upfront investment but can dramatically reduce lifecycle costs.

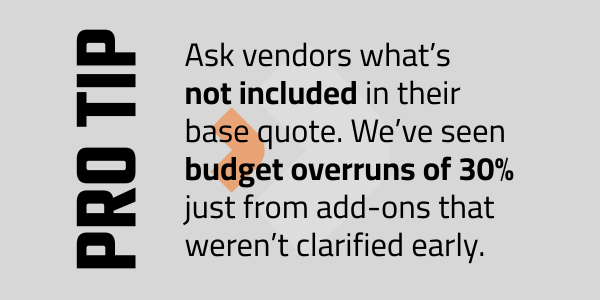

3. Hidden Costs: The Real Price of Downtime

When you’re comparing two quotes and thinking, “This one saves us $30,000,” ask yourself: what’s an hour of production worth if your line goes down?

For many CLOOS customers, downtime costs exceed $10,000 per shift. The cheaper system might save you $30K on paper—but lose you $100K in lost output due to support delays, part shortages, or poor diagnostics.

A premium system with robust service infrastructure pays for itself the first time something goes wrong.

4. Pre-Engineered vs. Custom: Budget Predictability vs. Flexibility

| Comparison Factor | Pre-Engineered Cell | Custom System |

|---|---|---|

| Cost Predictability | High | Variable |

| Lead Time | Shorter (8–14 weeks typical) | Longer (16–28+ weeks) |

| Best For | First-time adopters, job shops | High-volume, complex fab environments |

| Flexibility | Moderate | High |

| Risk Profile | Lower | Higher (if poorly scoped) |

Most of our customers who are new to automation start with a pre-engineered cell. The confidence, speed, and cost control make it the smart move—even for high-mix parts.

5. Should You Budget for More Than Just the System?

Yes. And here’s why:

| Additional Item | Typical Range (USD) |

|---|---|

| Shipping & Install | $5,000 – $15,000 |

| Training (Operators/Maintenance) | $3,000 – $10,000+ |

| Fixturing | $5,000 – $40,000+ |

| Service Contract (Year 1+) | $5,000 – $25,000/year |

6. What Should You Do Next?

Whether you’re pricing your first cell or evaluating system #5, here’s your next best move:

Request a Quote Discovery Call – No pressure, no scripts—just a straight answer on whether robotic welding makes sense for your shop.

Talk to a CLOOS Application Engineer – We’ll walk through your part, your goals, and your budget to give you a real-world cost range.