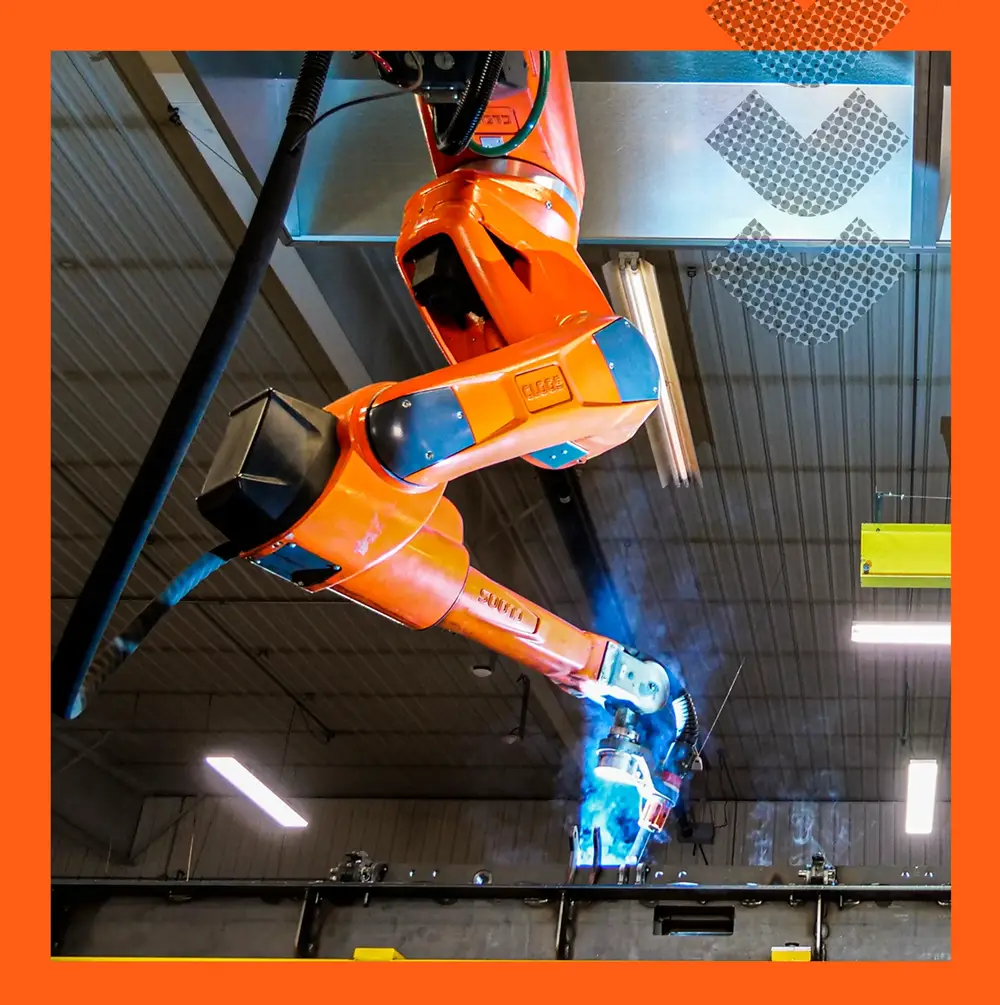

Welding Automation That Works for Construction and Heavy Equipment

- Home

- Construction and Heavy Equipment

From advanced systems capable of high-deposition, multi-pass welds to custom full-scale line automation, CLOOS delivers quality, consistency, and efficiency that stacks up.

When it comes to building construction and heavy equipment, challenges with skilled labor, quality, and reliability stand in the way of getting the job done.

Welding automation can address all of those concerns. But there’s a big difference between doing a job and doing it right.

At CLOOS, we help you put automation to work, combining high-tech robotics with high-touch mentorship to achieve what really matters: the highest quality weld.

Welding Automation Is Worth Doing Right

Boost Your Throughput

By automating routine steps like material handling and component welds, CLOOS custom systems have been shown to improve output by 3x or more.

Achieve Perfect Welds, Every Time

Robotic consistency helps reduce waste, eliminate the need for rework, and ensure quality down the line.

Build To Suit You

Our welding experts apply their deep, specialized knowledge to solve your most complex automation challenges.

Support Your Workforce

Our approach to automation complements skilled labor, helping to fill in production gaps and improving the work environment for your welders.See a Real Return on Your Investment

CLOOS pre-engineered systems deliver a rapid ROI in as few as 12 months. Even advanced custom solutions pay for themselves typically within two years.

Find the Help You Need, Right When You Need It

From consultation and installation to training, maintenance, and beyond, count on CLOOS expertise and guidance through it all.

“We’ve worked with CLOOS since 1998, and we’ve had a good relationship over all those years. We have great respect for CLOOS, for their products, their reliability, their service— everything. We always have great outcomes.”

-Construction Equipment Manufacturer

Uncompromising Quality, Weld After Weld

At CLOOS, everything that we do is focused on one thing: achieving the highest quality weld.

For us, automation isn’t just about implementing new tools to work faster. It’s about using technology to work smarter, making weldments stronger, processes more efficient, and shops more productive.

Single-Source Manufacturing

When quality is on the line, every part matters. That’s why we design and build every part of every system in-house, from the power source to the contact tip.

Hundred-Year Heritage

With over a century of welding innovation under our belt, we put our expertise and passion to work solving your toughest automation challenges.

FEATURE FOCUS

CLOOS custom systems have been shown to boost production by 3x or more, creating perfect weldments even in the most demanding applications, every time, across every shift.

In a world of labor shortages, that matters. Not only can automation fill the gaps of your production and boost throughput, but working alongside robotics reduces both manual welder fatigue and turnover. Win-win.

Expert Guidance, Every Step of the Way

Automating your process is a journey. You don’t have to go it alone. At CLOOS, our support goes beyond selling you a robot. You’ll have access to a team of welding experts who are with you through upgrades, downtime, and everything in between.

The Right Fix

We know welding and automation, but no one understands your needs like you do. We take the time to learn your specific processes and challenges to recommend the right solution.

Support That Never Quits

From initial consultation and training to maintenance and beyond, we're in it for the long haul.

Explore the Experience Center

Located at our North American headquarters in the Chicago area, the Experience Center is a state-of-the-art technology showcase and training center. Learn about our systems with the same folks who design, engineer, and build them. BYOP (bring your own part) to see first-hand how automation can enhance your process.

“Customer service is extremely important. If you don’t have it, it means you’re down. Whenever we have systems go awry, or programs don’t function as they’re supposed to, we just call CLOOS.”

-Link-Belt Cranes, Kentucky

Let’s Talk Shop

Get in touch with one of our product specialists. We’ll walk you through the options, answer your questions straight, and help you choose the welding automation that fits your shop – and your goals.

YOU MAY BE INTERESTED...

How Hyster Yale is Doing Automation Right

Learn how Hyster-Yale eliminated missed welds and streamlined service by automating critical production with integrated CLOOS systems.

How Link-Belt Cranes is Doing Automation Right

See how Link-Belt Cranes improved weld quality and reduced downtime using custom CLOOS automation for large, multi-pass weldments.

Custom Systems & Line Automation

CLOOS Robotic Welding, Inc. provides fully customized welding automation solutions, from complete automated lines to specialized applications. Our engineering services