If It’s Worth Doing,

It’s Worth Doing Right

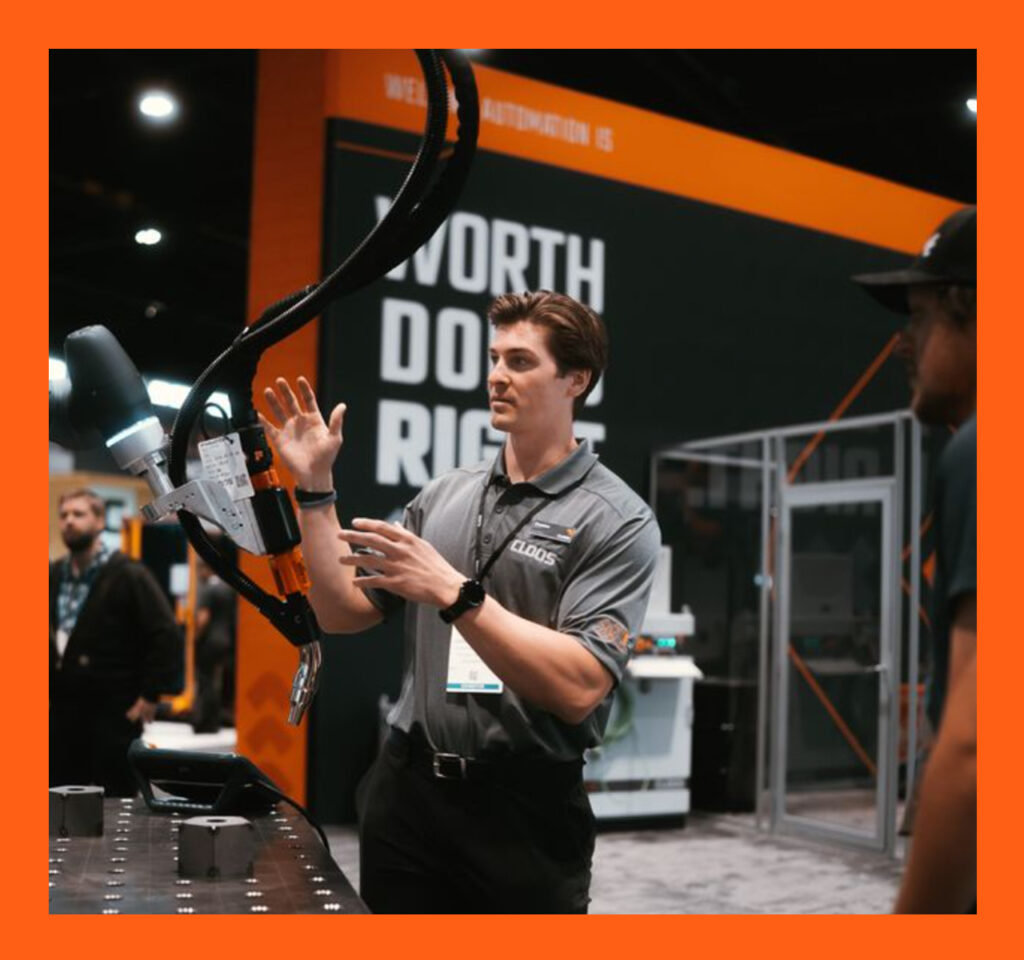

FABTECH 2025 May Be Over, but Automation Innovation Never Quits

Whether you stopped by the CLOOS Heavy Metal District or just you’re finding us for the first time, you’re in the right place.

We’re here to turn the insights from metal fabricating’s biggest trade show into actionable steps on your automation journey.

Ready To Take the Next Step?

Let’s continue the conversation. From implementing your first system to expanding your capacity, our team is ready to help you get it done right.

In Case You Missed It:

FABTECH 2025 Highlights

TANDEM+ is our revolutionary three-wire automated welding This year, we transformed the show floor into a shop floor at the CLOOS Heavy Metal District, demoing revolutionary automation innovations alongside reliable solutions that address real production challenges.

From TANDEM+ three-wire welding technology debuts to hands-on programming sessions, see what made this our most successful show yet.

Key FABTECH Takeaway

Facing the Future Head On

Skilled labor shortages, supply chain headaches, technological disruptions—challenges aren’t going away any time soon, but finding the right partner can help you stay ahead of the curve.

Doubling Down on Innovation

Nearly 30 years after pioneering two-wire tandem welding, we’re raising the bar and adding a wire. TANDEM+ demonstrations showed how a simple upgrade can achieve 30% productivity gains.

Programming Isn’t Just for Programmers

Where other booths led with carnival games, we took a different approach to friendly competition. Hands-on robotics programming challenges showed just how accessible automation can be.

Building a Relationship > Buying a Robot

FABTECH is proof that just about everyone has a solution to sell. The real test is whether they’ll be there to help you succeed with it. The right equipment needs the right partner.

Standing by Your Product and Your Customers: That’s Doing It Right

At FABTECH, we heard the same concerns from customers over and over: “What happens after you sell me the system?”

Too many had horror stories about systems from other vendors that sizzled at the show and fizzled in the shop. With no post-sale support, customers couldn’t figure out how to integrate automation, making their shiny new robot an expensive regret.

That’s why we’re excited to introduce CLOOS Cares, our systematic response to the automation trust deficit.

CLOOS Cares at a Glance

$5,000 Delivery and Installation Guarantees

Your production schedule matters. If your shipment is delayed or we miss your install timeline, even for factors beyond our control, we’ll provide $5,000 worth of free wear parts.

$1.5 Million Parts Inventory

We’re committed to getting you the right parts right when you need them. Together with our worldwide logistics network, you can get back up and running when downtime strikes.

One Point of Contact To Count On

Exhausted from the runaround? With CLOOS, every system gets a dedicated project manager there to support you from purchase order through installation.

Going All-In on Onboarding

Competence builds confidence. Count on comprehensive operator training at our state-of-the-art Experience Center in Chicago or at your site with your own equipment.

Next-Generation Welding Is Here:

TANDEM+

TANDEM+, our revolutionary three-wire welding technology, made its North American debut at FABTECH. Here’s what you need to know.

One More Wire – 30% More Throughput

- Higher deposition compared to traditional tandem welding

- Fewer layers required, reducing cycle time and rework

- Available as an upgrade to select existing systems.

We invented two-wire tandem welding back in 1996. We didn’t stop innovating then, and we’re not stopping now.

Hurry Up and Weld:

Pre-Engineered Systems

Another common question at FABTECH: “When can we get started?”

With our easy-to-program pre-engineered systems, the answer can be: “Right now.”

Available Systems

- ArcBoT Collaborative Systems

Job shop-friendly automation that works with your team.

- Expert Arc Series 05, 10, and 20

Scalable solutions from simple cells to complex production lines.

Stay Connected to Welding Automation Insights

Get practical tips, industry updates, and automation insights delivered to your inbox. No sales pitches. Just straight talk to make informed decisions.

Automation in Action

Even though we’re a welding robotics company, we know that our customers’ products take center stage. At FABTECH 2025, we showcased real equipment donated by our partners.

Your industry has unique challenges. See how CLOOS systems, solutions, and mentorships makes the difference between getting the job done and getting the job done right.

CLOOS for Job Shops

Ready-to-ship systems that are ready to get to work.

CLOOS for Heavy Equipment

Welds that stand up to toughest demands.

CLOOS for Trucks and Trailers

Solutions that go the distance.

CLOOS for Agricultural Equipment

Automation that’s outstanding in the field.

Connect With a Welding Automation Expert

Exclusive Discounts on Ready-To-Ship Systems

A Full Schedule of Automation Know-How

From ready-to-ship systems to custom solutions, we’ll work with you to design an approach that suits your industry and your operation.

Here To Help You Get Automation Right

After 40+ years operating in North America, we know that automation is a journey. The right partner will help you go far. From your first system to custom full-scale line automation, count on CLOOS to be there every step of the way.