Most shops still treat robotic welding like it belongs in a box. Fixed cells. Fixed parts. Fixed thinking.

But the real gains in welding automation are happening outside the traditional envelope. Manufacturers that work with long, heavy, or variable parts are finding smarter ways to move the robot to the part instead of the other way around.

Here is how modern automation systems are breaking the mold and creating new flexibility for welders building the complex, the large, and the high-mix.

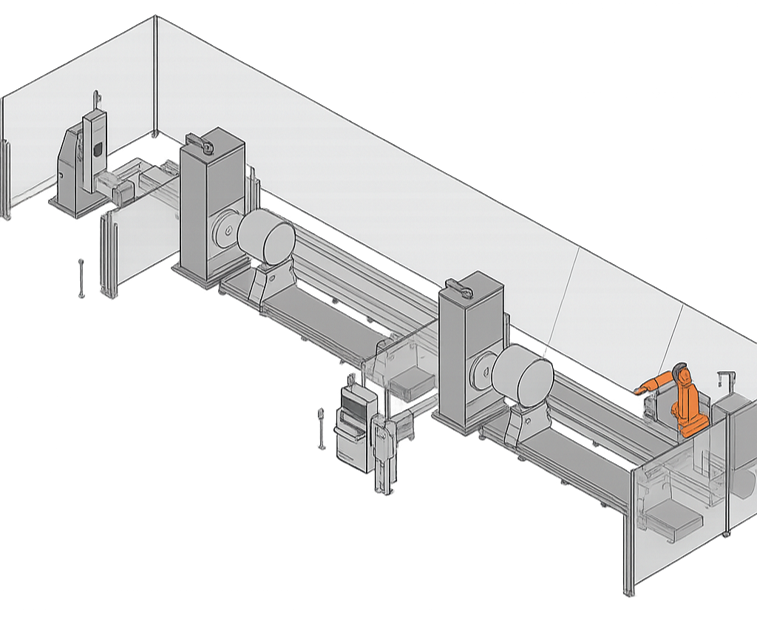

Go Beyond the Box with Track-Mounted Robots

Fixed welding cells limit how far your system can scale. Track-mounted robots give you:

- Expanded reach for trailers, chassis frames, and structural assemblies up to 40 feet

- Reduced handling by letting the robot travel instead of repositioning heavy parts

- Multi-station workflow to keep one robot productive across multiple weld zones

Use Case:

A 7-axis robot runs along a floor track and serves three stations. With a skyhook and dual headstock setup, operators stay off the floor while parts stay in flow.

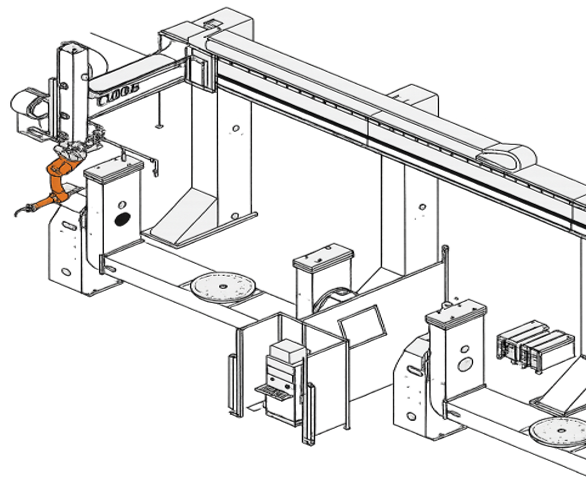

Elevate Access with Multi-Axis and Gantry Robots

Ground-mounted robots only go so far. Gantry-mounted systems and multi-axis positioners open up more weld paths without crowding your floor.

- Top-down access for large weldments when floor space is limited

- Torch angle control that maintains consistent weld profiles

- Dual-station builds so loading does not interfere with arc time

Use Case:

A 3-axis gantry paired with dual-axis drop-center positioners delivers full access to complex assemblies without manual flipping or repositioning.

Use Part Positioning to Improve Quality and Safety

Robotic welding is not only about reach. It is also about part orientation and weld access.

- Better welds from flat and horizontal positions

- Fewer injuries by eliminating the need for manual rotation

- Higher throughput from automatically sequenced positions

Key Insight:

A well-matched positioner reduces rework, shortens cycle times, and eliminates the need for human lift-assist devices during setup.

Coordinate More Than Welding

Advanced systems are no longer just about arc time. They manage entire workflows.

- Coordinated welding with two or more robots working in tandem

- Material handling via robotic pick-and-place between weld stations

- Post-weld finishing using tool changers for grinding or part prep

- Integrated inspection with sensors and in-line quality checks

Result:

The system delivers welds with more consistency, less waste, and fewer stops from manual handling or verification.

Rethink the Line with Dynamic Layouts

Not all parts follow the same path. High-mix environments need flexible system layouts.

- Robotic cells in series for parts with multiple weld zones

- Conveyor integration that maintains part orientation

- Vision systems that detect variation in part size or placement

- Smart controls that sequence operations without operator input

Use Case:

A structural fabricator produces stair stringers of variable length. With vision-guided placement and automated handling, the robot adjusts its weld path on the fly.

The Future of Robotic Welding Is Flexible, Mobile, and Intelligent

Manufacturers are no longer designing cells. They are designing systems.

- Machine learning optimizes weld routines in real time

- Mobile robots travel between stations as needed

- Auto-generated programs reduce downtime and programming bottlenecks

If your current layout feels restrictive, the next step might not be bigger equipment. It might be smarter automation.

Looking to expand beyond a fixed cell?

Let us walk through your part mix and workflow. We will help you identify whether a track, gantry, or layout change could give you the flexibility you need.